In the world of construction, the choice of building materials holds significant importance not just in terms of structural strength and aesthetics but also regarding environmental impact. In recent years, there has been a growing awareness and emphasis on sustainability in construction practices. Among the many materials used, natural stone, particularly granite, has emerged as a sustainable and eco-friendly option, notably due to its low grey energy footprint.

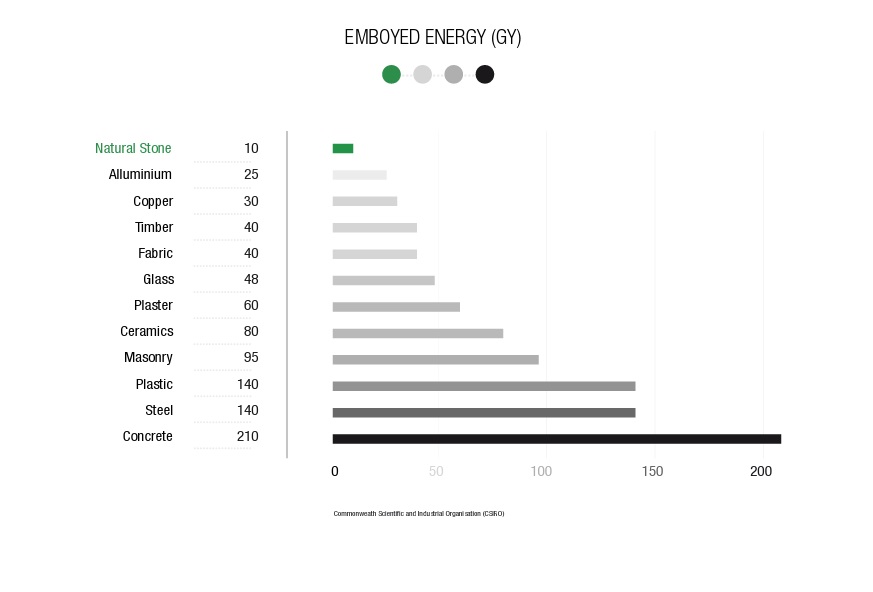

Before delving into the sustainable aspects of granite, it’s crucial to understand what grey energy is and why it matters in construction. Grey energy, also known as embodied energy, refers to the total energy consumed throughout the life of a material. This includes energy used in extraction, processing, transportation, installation, maintenance, and eventual disposal or recycling. Calculating grey energy provides a comprehensive view of a material’s environmental impact, encompassing both direct and indirect energy consumption.

Granite Vs Engineered Stone: A Grey Energy Consumption Comparison

When comparing granite to engineered stones like quartz or marble, the difference in grey energy consumption becomes starkly evident. Studies conducted by reputable organizations have shown that granite possesses a significantly lower grey energy footprint. For instance, while granite typically has a grey energy value of around 33.3 MJ/m³, engineered stones can range from 100 to 200 MJ/m³ or higher, depending on their manufacturing processes and materials used.

In addition to sustainability issues, the manufacture of engineered stones also increases the risk of Silicosis amongst workers in the industry. The health risks associated with silicosis in the engineered stone industry is so high that countries have begun to pass legislature against it. Australia for example became the first country to prohibit the use, supply and manufacture of all engineered stone, starting in 2024.

This substantial difference underscores the sustainability of granite as a building material. Its lower grey energy consumption translates to reduced environmental impact across its entire lifecycle, making it a preferred choice for eco-conscious construction projects.

The Sustainable Advantages of Granite:

- Abundance and Longevity: Granite is a naturally abundant material found in various regions worldwide. Its durability and resistance to wear and tear ensure longevity, reducing the need for frequent replacements and associated energy costs. This longevity contributes significantly to its overall sustainability.

- Minimal Processing Requirements: Unlike engineered stones that often require extensive processing involving resins, additives, and energy-intensive manufacturing techniques, granite typically undergoes minimal processing after extraction. This simplicity in processing not only reduces grey energy but also minimizes waste generation and environmental impact.

- Energy-Efficient Extraction Practices: Modern quarrying practices for granite have become increasingly energy-efficient and environmentally conscious. Technologies such as diamond wire saws and water recycling systems help minimize energy consumption and waste generation during the extraction process, further enhancing granite’s sustainability credentials.

- Recyclability and Reusability: Granite is a highly recyclable material. Waste granite from quarries can be crushed and used as aggregates in concrete or road construction, promoting circular economy principles and reducing the demand for new materials. Additionally, granite can be reused in various applications, further extending its lifecycle and reducing environmental strain. Granite slurry for example can be used as an ingredient in the manufacture of compressed bricks.

- Aesthetic Appeal and Timelessness: Apart from its sustainability attributes, granite is renowned for its natural beauty, durability, and timeless elegance. Its unique variations in color and pattern add character to buildings, enhancing their visual appeal and contributing to a sustainable yet aesthetically pleasing environment.

In an era where environmental consciousness is at an all-time high, the construction industry is increasingly embracing sustainable practices and materials. By prioritizing materials like granite with lower grey energy footprints and inherent eco-friendly characteristics, construction projects can significantly reduce their environmental impact while ensuring structural integrity and visual appeal.

Educating stakeholders, including architects, builders, and consumers, about the benefits of sustainable materials like granite is essential in fostering a culture of environmental responsibility in construction. Governments and regulatory bodies can also play a vital role by incentivizing and promoting the use of sustainable materials through policies and certifications.

Granite’s sustainable brilliance in construction lies not only in its lower grey energy footprint but also in its abundance, durability, minimal processing requirements, energy-efficient extraction practices, recyclability, and timeless aesthetic appeal. As the construction industry continues to progress towards sustainability, embracing materials like granite paves the way for the development of more sustainable environments.

In a world where sustainability is becoming increasingly crucial, innovative solutions are emerging to tackle waste while creating durable products. One such promising avenue is the utilization of granite sludge in the production of compressed stabilized earth blocks (CSEBs), offering a sustainable alternative for construction materials.

Granite, a popular choice for countertops and monuments, generates a by-product known as granite sludge during the cutting and polishing processes. Traditionally, this sludge has posed environmental challenges due to its disposal. However, recent studies and experiments have showcased its potential to revolutionize the construction industry.

What are Compressed Stabilized Earth Blocks (CSEBs)?

Before delving into the utilization of granite sludge, let’s understand what CSEBs are. These blocks are made from a mixture of soil, stabilizers (like cement or lime), and sometimes additives for specific properties. They are compressed under high pressure to form sturdy building blocks used in walls and other structures.

The Eco-Friendly Journey of Granite Sludge

The journey of granite sludge from waste to a valuable resource begins with its collection from stone processing units. Instead of being discarded, this sludge can undergo treatment and processing to become a key ingredient in CSEBs.

- Enhancing Strength and Durability: Research has indicated that incorporating granite sludge into CSEBs can enhance their compressive strength and durability. The fine particles in the sludge fill gaps between soil grains, resulting in a more compact and robust block.

- Environmental Benefits: By utilizing granite sludge, we not only reduce waste but also decrease the environmental footprint associated with traditional building materials. This eco-friendly approach aligns with sustainable construction practices and promotes a circular economy.

- Cost-Effectiveness: In addition to its environmental advantages, using granite sludge can also offer cost savings. As a by-product, it is often available at lower costs compared to primary materials, making it an attractive option for builders and developers.

Real-World Applications and Success Stories

Several projects around the world have showcased the practicality and effectiveness of incorporating granite sludge into CSEBs:

- Case Study 1: Sustainable Housing in India

A construction project in India utilized CSEBs made with granite sludge. The resulting structures demonstrated excellent strength and thermal insulation properties, contributing to sustainable housing solutions in the region. - Case Study 2: Community Initiatives in Africa

Community-driven initiatives in Africa have embraced the use of CSEBs incorporating waste materials like granite sludge. These initiatives not only promote environmental stewardship but also empower local communities through skill development and employment opportunities.

Embracing Sustainable Building Practices

As the demand for sustainable building materials continues to rise, solutions like using granite sludge in CSEBs offer a glimpse into a greener future for construction. By leveraging waste streams effectively, we can reduce environmental impact, improve structural integrity, and foster innovation in the building sector.

In conclusion, the journey from waste to wealth is exemplified by the transformative potential of granite sludge in creating durable and eco-friendly compressed stabilized earth blocks. This paradigm shift towards sustainable practices underscores the importance of reimagining waste as a valuable resource in building a more resilient and environmentally conscious world.

Transforming Waste into Strength: Exploring the Potential of Granite Sludge in Sustainable Construction

In today’s era of sustainable development, the construction industry is undergoing a transformative shift towards eco-friendly practices. One innovative approach gaining traction is the utilization of granite sludge, a by-product of stone processing, in creating durable building materials such as compressed stabilized earth blocks (CSEBs). This not only addresses waste management challenges but also contributes to the circular economy and reduces environmental impact.

Understanding Compressed Stabilized Earth Blocks (CSEBs)

Before delving into the multifaceted uses of granite sludge, let’s first understand the concept of CSEBs. These blocks are crafted from a mixture of soil, stabilizers (such as cement or lime), and sometimes additives for specific properties. They are compressed under high pressure to form robust building blocks suitable for various construction applications.

The Environmental Journey of Granite Sludge

Granite sludge, typically generated during the cutting and polishing of granite for countertops and monuments, has historically posed disposal challenges. However, recent advancements have unveiled its potential as a valuable resource in sustainable construction practices.

- Enhancing Structural Integrity: Studies indicate that incorporating granite sludge into CSEBs enhances their compressive strength and durability. The fine particles in the sludge fill voids within the soil mixture, resulting in denser and more resilient blocks.

- Environmental Benefits: By repurposing granite sludge, construction industries can significantly reduce waste sent to landfills, thereby mitigating environmental impact. This approach aligns with global efforts towards waste reduction and promotes resource efficiency.

- Cost-Effectiveness: Utilizing granite sludge in CSEBs not only benefits the environment but also offers cost savings. As a by-product, it is often available at lower costs compared to primary materials, making it a viable and economical choice for builders and developers.

Real-World Success Stories and Promising Initiatives

Numerous real-world projects exemplify the successful integration of granite sludge into sustainable construction practices:

- Case Study 1: Green Building Projects in Europe

European green building initiatives have embraced the use of granite sludge in diverse applications, from eco-friendly pavements to aesthetically pleasing architectural features. These projects showcase the versatility and environmental benefits of utilizing waste materials innovatively. - Case Study 2: Infrastructure Development in Emerging Economies

Infrastructure projects in emerging economies have leveraged granite sludge to address infrastructure challenges sustainably. By incorporating waste-derived materials into construction practices, these initiatives promote resource conservation and resilience.

Beyond CSEBs: Exploring Alternative Uses of Granite Sludge

While CSEBs represent a significant application of granite sludge, this versatile material holds potential for various other uses within the construction and manufacturing sectors:

- Sustainable Pavement and Road Construction

Granite sludge can be incorporated into asphalt mixes or used as a base material in road construction. Its fine particles contribute to improved pavement durability and can reduce the need for virgin aggregates, thereby promoting sustainable infrastructure development.

- Eco-Friendly Concrete Production

In the realm of concrete production, granite sludge can serve as a partial replacement for traditional aggregates. This not only reduces the demand for natural resources but also enhances the concrete’s mechanical properties and resistance to environmental degradation.

- Decorative and Architectural Applications

Beyond structural elements, granite sludge can find use in decorative and architectural applications. It can be processed into innovative surface finishes, artistic sculptures, or sustainable building facades, adding aesthetic value while supporting sustainable design principles.

Embracing a Greener Future

The journey from waste to wealth, epitomized by granite sludge’s transformative potential, underscores the importance of embracing sustainable practices in construction and manufacturing. As industries increasingly prioritize environmental responsibility, innovative solutions like utilizing waste materials become catalysts for positive change.

In conclusion, granite sludge represents more than just a by-product of stone processing—it embodies a sustainable resource with vast potential across various sectors. By harnessing its properties in creating durable building materials and exploring alternative applications, we pave the way towards a greener and more resilient future.

References

https://medcraveonline.com/MOJCE/utilization-of-granite-sludge-in-the-preparation-of-durable-compressed-stabilized-earth-blocks.html

Case Study 1 – https://ec.europa.eu/energy/topics/energy-efficiency/energy-efficient-buildings/green-building-projects_en

Case Study 2 – https://www.worldbank.org/en/topic/infrastructure

Looking for premium wholesale granite countertops in a wide variety of colours? Want multiple finish options like polished, honed, leathered, flamed etc? You have come to the right place here at Kattima Granite, India. We are a 40+ year old award-winning granite export company. We currently export granite monuments, slabs (gangsaw and cutter sizes) and rough blocks of our granite to customers all over the world, to USA & Canada to China to Taiwan to Australia.

We can currently ship out wholesale granite countertops in as little as 30 to 45 days, to your choice of destination port. Please learn more about the various wholesale granite countertops we have to offer today.

Our Selection of Wholesale Granite Countertops at Kattima Granite

Minimum Order Quantity (MOQ) = 1 Container | Shipping in: 30-60 Days | Sizes Available: Gangsaw/Cutter (in 16mm, 20mm and custom thickness)

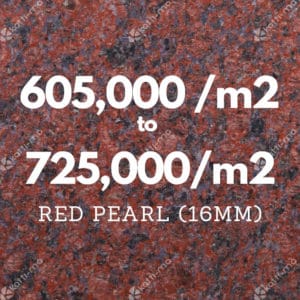

Wholesale Red Pearl Granite Countertops

Red Pearl is an exclusive stone from Kattima Granite. Only we have ownership and access to the quarry that produces this bold and beautiful stone. A close relative to Ruby Red, another very popular red granite, Red Pearl is distinctly characterized by its dark and beautiful swirls and grains.

Besides offering a striking appearance that can be leveraged to beautify and enhance both indoor and outdoor spaces or as cladding for facades, Red Pearl is also an incredibly robust granite, needing very little maintenance. It is scratch-proof and weather resistant.

Order Wholesale Red Pearl Granite Countertops Here

Prices start @$25 per Sq.Mt FOB India

Wholesale Cladon Blue Granite Countertops

Cladon Blue is another beautiful Kattima Exclusive stone! It has a striking resemblance to steel Grey granite. In fact, the resemblance is so strong that it can easily substitute Steel Grey granite, but with a much more affordable price tag. The only difference between Steel Grey and Cladon Blue is the slight bluish tint on the grains. Frankly, Cladon Blue is an upgrade from Steel Grey when it comes to appearance and aesthetics.

Being a neutral color, it can be used anywhere, seamlessly. It is particularly popular as a material for building facades.

Order Wholesale Cladon Blue Countertops Here

Prices start @$20 per Sq.Mt FOB India

Wholesale Brown New Caledonia Granite (Costa Dakota) Countertops

Probably the rarest granite in India at the moment. Costa Dakota is yet another Kattima Exclusive. It has a remarkable appearance to New Caledonia granite in terms of textures and patterns, in a brown avatar.

It’s a fantastic choice of countertops for homes with a classic, modern-classic or earthy look. Kattima Granite can provide this beautiful brown granite in a variety of finishes that can suit several applications both interior and exterior. At any time, Kattima Granite has a supply of wholesale brown New Caledonia granite is both light and dark colours. Please request samples to learn more about this stunning granite.

Order Wholesale Brown New Caledonia (Costa Dakota) Granite Countertops Here

Prices start @$20 per Sq.Mt

Wholesale Kuppam Green (River White) Granite Countertops

A fantastic choice for kitchen countertops are our Kuppam Green slabs. They look very similar to the premium and very popular River White granite. Only on close inspection can you notice very light green waves cascading across the surface of the slab, giving it its Kuppam Green name.

Order Wholesale Kuppam Green (River White) Granite Countertops Here

Prices on Request

Wholesale Viscont White Granite Countertops

Also known as Viscount White or Viskont white, this is a premium granite that was probably the most popular white granite in 2022. It features beautiful swirls of black and grey swirls against a white backdrop. It’s the chaotic and unpredictable contrast between the light and grey that makes this a visually stunning granite to look at. Now to Viscount white countertops are the same, another feature that just adds to the allure of this granite.

Order Wholesale Viscount White Granite Countertops Here

Prices start @$22 per Sq.Mt

Wholesale Steel Blue Granite Countertops

A fantastic material for commercial and large-scale uses, Steel Blue is often used as wall cladding or for outdoor landscapes. But, there’s no reason why it won’t make a great countertop surface as well, especially for mass projects. Besides featuring a striking blue color, Steel Blue is also very easy to maintain and is very affordable, especially when you buy wholesale from Kattima Granite.

Order Wholesale Steel Blue Countertops Here

Prices start @$18 per Sq.Mt FOB India

Wholesale India Black Granite Countertops

Black countertops are timeless and are a choice that you just cannot go wrong with. And Kattima Granite has the most premium wholesale India Black or Absolute Black granite that you can import from India. The stone’s main features are an uncompromisingly deep and rich black surface on a surface that has almost no porosity. It’s a very dense granite.

You can opt for the very popular polished finish or choose one finish styles such as honed, flamed, leathered or bush-hammered, if you are looking for a more sophisticated and uncommon countertop.

Order Wholesale Absolute Black Granite Countertops Here

Prices on request

Other Wholesale Granite Countertops

Besides our exclusives popular colors mentioned above, Kattima Granite also deals in wholesale granite slabs for colors such as Paradiso, Bahama Blue, Elephant Grey, Mint Grey, Meera White, Steel Grey, India Mist, Indian Mahogany, Black Galaxy, SADG (South African Dark Grey), Mint Green (Uba Tuba), Black Forest, Imperial Brown, Moon White, Black Pearl and Regal Black. Please contact us for more information on our current stock, shipping times, finish styles and pricing. We will be happy to assist you.

When it comes to granite countertops, polished and honed are easily the most popular finish styles. But, leathered is another finish that has been steadily gaining popularity over the years. Let’s learn more about this particular finish style.

What is a leathered granite finish?

It’s called a leathered finish because the granite actually feels like you are running your hands over leather. The granite is non-reflective and has a subtle matte finish. It’s very popularly used on dark colours but can be used on lighter colors as well, like a leathered Viscount white granite finish. But the main characteristic of this finish style has to do with the texture.

One can both feel and look at the texture. Unlike polished surfaces that are glossy and smooth, a leathered surface will feature subtle pits and fissures, lending it a very natural look. You however don’t have to worry about the surface being uneven though. Your countertop will not present problems where your plates or cutting boards rock around. What it will do is give you a countertop that looks and feels very unique.

Who will like leathered granite countertops?

Anyone who loves a natural look will love a granite countertop with a leathered finish. Unlike polished finishes that look great but offer little touch appeal, leathered granite countertops will feel rustic. People who go with a leathered finish on their countertops often enjoy great appreciation from visiting guests who invariably find the granite countertop to be a conversation piece.

Some granite stones like veined or speckled granites are particularly good candidates for a leathered finish as the stone’s patterns come alive not just visually but by feel as well. It’s a fantastic finish style to choose for homes with a rustic, earthy or with subtle deco themes.

How is the leathered granite countertop finish created?

It takes experienced hands to create a beautiful, leathered finish on any countertop. At Kattima Granite, we have experienced granite finishing craftsmen who know exactly how to achieve a leathered finish that will match an architect’s vision for the granite. Leathering is achieved by using diamond tipped brushes to run over the entirety of a slab’s surface.

These diamond-tipped brushes are available in many grits and different grits produce different results. Even the pressure and duration of brushing applied on these brushes will dictate the quality and appeal of a leathered finish. At Kattima, all of our stones are offered in a leathered finish. Please see examples of leathered finishes on our stones below. If you are after a very particular leathered look, you can talk to us about the aesthetics you have in mind, and we will go to great lengths to create that exact vision you have in your mind.

Below is the selection of beautiful leather finish granite stones Kattima Granite offers.

- New Caledonia Leathered Countertop

- Steel Grey Leathered Countertop

- Steel Blue Leathered Countertop

- Viscount White Leathered Countertop

- Paradiso Leathered Countertop

- Red Pearl Leathered Countertop

Advantages of Leathered Finish Countertops

Brings out the natural beauty of Granite

Granite is a natural stone, and a leathered finish lets granite show itself off as the beautiful natural stone that is. Minute fissures, pits and veining you can feel and give your countertop an earthy feel, like you have unprocessed and beautiful stone in your home.

Low maintenance

Granite generally is a very low-maintenance stone. But leathered finishes take low maintenance to another level. The brushing with diamond-tipped brushes tightens the stone’s pores. As a result, it is very, very stain resistant and also water spot resistant. It’s also very durable and easy to clean. Some soap water and a soft bristle brush is all that’s needed to keep your countertop looking gorgeous for years.

Unique!

Granite is easily the most popular stone of choice for countertops. While there are hundreds of colours of granites, most people opt for a polished or honed finish. Opting for a leathered finish will leave you owning a countertop that looks stunningly unique.

Disadvantages of Leathered Finish Countertops

Can make small kitchens look smaller

Because leathered finishes are non-reflective in nature, they can make small kitchen counters look even smaller. Choose a leathered finish only when you plan to create ample countertop space with your granite.

Ideal only for a single countertop, without seams

Since leathered countertops have texture that you can feel and see, they are not an ideal choice when you are trying to create your countertop with more than one piece. Unlike polished or even honed finishes that can be joined in a seamless way, leathered finishes tend to show up as separate pieces at the seams.

A headstone is a memorial monument used to commemorate the life of a deceased loved one. There are many types of headstone monuments to choose from. Here at Katti-Ma Granite, a leading wholesale granite monument supplier, we give you a quick and easy guide to help choose a headstone for a loved one that has passed on. You can also download Katti-Ma’s monument catalog to explore more styles to choose from.

Headstones are usually classified into the following broad types; Uprights, Slants, Flat or Bevel Markers, Benches and Wings.

Upright headstone monument

Upright headstones feature various styles of tops. The most popular top is a serpentine or SERP top. Other popular top styles are rooftop, oval tops, flat tops or rounded corner tops. Upright headstones are often paired with a matching vase or vases.

These headstones are available as both single uprights and also as companion uprights

Slant headstone monuments

It is recommended that slant headstones be placed on a base and not directly upon the foundation. Like upright headstones, slants can also have tops in various styles, as described earlier.

Flat or Bevel Headstones

Often chosen as an affordable or minimalistic headstone, these are nothing but flat rectangular markers that are about 4 inches thick. They are placed horizontally on the ground. Bevel markers are slightly raised in the back, giving them a slope.

Bench Headstones

Wing Headstones

Wing headstones are often chosen to celebrate the life of a loving couple that have passed on. They consist of two dies or tablets that are separated by a pedestal or plinth or other sculptures like a base or angel.

Children’s headstones

No family should have to go through the process of choosing a headstone for a little one that has passed on. Headstones to commemorate the lives of young ones feature granite sculptures that depict toys, musical instruments, teddy bears or angels. Children’s headstones are usually ordered on a bespoke basis, designed and built according to the grieving family’s needs.

Choose a Headstone Type that will be approved by your Cemetery

Not many people know that almost all cemeteries have restrictions and guidelines when it comes to the type of headstones they will allow in their cemetery. These restrictions vary from cemetery to cemetery. It is best that you contact your cemetery to find out their particular restrictions. Restrictions are usually applied to the following aspects of a headstone.

Headstone type – Not all headstones are allowed by all cemeteries. There are some cemeteries that only allow grave markers while most will allow a wide array of headstone types, like the ones we detailed earlier.

Headstone size – Cemeteries will list out size restrictions for both single and companion headstones. These are usually 24 x 12, 28 x 16, 18 x 24 for singles and 36 x 18, 44 x 14 for companion headstones.

Headstone material and colour – While most cemeteries do not have color restrictions, there are some that are quite particular about the shade of headstones they will permit on their cemetery. When it comes to materials, granite is accepted by all cemeteries when it comes to monuments.

Custom artwork – Some cemeteries have specific restrictions on things like types of artwork, photo memorials made out of porcelain and so on. If the headstone you choose has art or other elements that is not found on a traditional headstone, it is best that you seek the cemetery’s approval beforehand.

Do you have to buy a headstone only from the cemetery where your loved one is buried?

The answer is no. Federal law gives you the right to buy your headstone from any vendor of your choice, whether or not they are affiliated with the cemetery. Cemetery owners will however try to talk you into buying headstones from memorial companies that they own or are only affiliated with them. They do this by either imposing installation fees on 3rd party vendor headstones or by trying to simply insist that you buy your headstone from their memorial services. You can however quote the federal law and exercise your freedom to work with any vendor of your choice.

New Caledonia, also known as Canadian Brown or Caledonia granite is a very popularly used granite stone across the world. Sporting a subtle and neutral array of white and grey speckles, it’s no surprise that this granite is as popular as it is, capable of seamlessly blending into and complementing modern kitchen and exterior architectural landscapes. But what if you love the New Caledonia granite but want an earthier brown color to replace the neutral greys? That’s exactly what’s on offer with Costa Dakota, an exclusive New Caledonia brown granite from Katti-Ma Granite.

Costa Dakota – A New Caledonia Brown Granite

Pattern

Costa Dakota features a unique pattern that disburses speckles of gold, brown, yellow, black and sometimes red and pink, in a chaotic yet beautiful pattern. The result is a visually stunning surface that is earthy, warm and vibrant, capable of lending a great amount of character to any architectural landscape. Be it indoor as a kitchen countertop or outdoors on wall cladding, Costa Dakota enhances the feel and appeal of its space.

Though the aesthetics are far more strikingly apparent than what you will see in the grey New Caledonia granite, Costa Dakota still remains neutral in whatever environment it is immersed into. This gives it a versatile use case scenario for both modern and classical construction styles.

Durability

Costa Dakota granite is extremely durable, making it a practical choice for indoor and outdoor applications. The stone features low porosity and high-heat resistance, making it a perfect kitchen countertop candidate to house even the busiest of stovetops. Outdoors, installed as wall cladding, the granite will last decades without cracking, chipping or excessively fading, thanks to its natural robustness and resilience to the elements.

It should be noted that Costa Dakota has a very high score on Mohs hardness scale.

Maintenance

Featuring very closely packed pores, Costa Dakota is one of the least porous granites in the world. This translates to very easy maintenance, especially when used as kitchen countertops. Any quality granite sealant will protect the gloss of this beautiful granite for years at a time.

Finishes

Katti-Ma Granite has the ability to provide Costa Dakota granite in a wide range of finish styles. Our most popularly requested finish styles are polished and leathered finishes. We also offer honed and flamed finishes.

- Polished

- Leathered

- Honed

Applications

As mentioned earlier, the low maintenance requirements and high-heat resistance make Costa Dakota a great kitchen countertop material. It’s also very popular as wall cladding for the same reasons, when exposed to sun and rain. Its low water porosity also makes it an excellent building material in wet areas such as landscaping around bathtubs, swimming pools, shower areas etc.

Consistency & Variance

Unlike New Caledonia granite which features rather significant variance on the stone’s surface over even 2,000 to 3,000 square feet of coverage, Costa Dakota provides a uniform pattern presentation for much larger coverage areas. This makes this New Caledonia Brown granite an excellent choice as brown natural stone of choice for applications that require widespread surface area coverage.

Our Costa Dakota Granite Projects

Below are just a few of our landmark Costa Dakota projects, featured from all over the world. Primarily used as wall cladding by our customers, Costa Dakota has been able to infuse style, sophistication and prestige into our customer’s buildings and architecture.

Wholesale New Caledonia Brown Granite from Katti-Ma Granite

With over 40 years in the business, Katti-Ma Granite has the ability to supply this stunning New Caledonia Brown Granite to any port in the world, in 30-45 days. Mined from our own quarries and marked and cut into rough blocks or slabs with great care, Katti-Ma can be your natural stone supply partner capable of providing you with a constant and quality supply of this unique brown granite.

Our customers feature builders and construction companies all over the world from countries such as USA, Canada, Taiwan, China, Australia and many more. Learn more about Katti-Ma Granite here. Get in touch with us here.

Get This New Caledonia Brown Granite in 30-45 Days, anywhere in the World

Granite is one of the most widely used natural stones for kitchen countertops. It does a fantastic job of naturally resisting stains and heat, making it an ideal surface for even the busiest of kitchens. That being said, granite countertops do require some cleaning and maintenance as they are a porous material. You must also remember that lighter granite surfaces require a little more cleaning care and maintenance than darker shades of granite.

Below, you will learn several key tips that will have your granite countertop looking brand spanking new, for several years or even decades to come!

How to deep clean granite countertops?

Keeping your granite countertops clean and pristine looking is a fairly easy process, if you follow the steps mentioned below. It is sufficient to carry out this recommended cleaning just once a week once every two weeks, as long as you generally wipe down your countertop every day.

Clear your countertop – First things first, remove all items placed on your granite countertop. This includes large appliances like mixers, blenders or food processors that you normally don’t move. This is important because areas under these large appliances can sometimes collect dirt and debris that can look very different from other areas on your countertop, when you do decide to move them

Clear loose debris – With a dry and soft sponge, gently push away all loose debris that has accumulated on your granite countertop

Warm dish soap + water + soft towel/sponge – Use warm water with a mild dish detergent to gently clean your granite countertops, one small area at a time.

It’s important to remember that you must not muscle your way into this cleaning. Gentle scrubbing is more than enough. To tackle stains that won’t come away easily, you can follow additional cleaning tips mentioned below

Tackling tough stains – For stubborn stains, use one of the following appropriate methods;

Hardened debris – Food or organic matter that has hardened over time can be easily scraped away from a granite countertop. Use a razor blade at a 45° angle to gently dislodge the matter. Follow it up with a quick towel and dish soap scrub. Granite is quite scratch resistant but you must still use a razor blade gently and only at the advised angle, to avoid any scratches

Stubborn stains – For stains that won’t go away with gentle scrubbing, create a paste using baking soda and water. Apply this paste on the stained area of the granite and wait for between 5 and 30 minutes. Then, use a wet towel to wipe away the paste. It is important that you do not scrub away at this paste that you have applied on your granite.

If the paste has hardened and won’t come off with a towel wipe, you can use the flat end of a soft silicone or plastic spatula to gently scrape away the hardened paste. Then, follow it up with a soap and towel wipe.

Really stubborn stains – If a stain won’t come off even with the above described soak and clean method with baking soda and water, you can simply try it again. But this time, let the paste sit on the stain for 24 to even 48 hours! Once you have applied the paste, cover it with a plastic wrap like cling-wrap. Then, use tape to hold down this plastic wrap smothering the paste over the stained area of your granite. Poke a few holes to ventilate this patch. After 24 or 48 hours, gently scrape or wipe away the paste as mentioned above. Having such really stubborn stains could mean that your granite could use a coating of sealant. More on that later in this post.

Disinfecting your granite countertop – This is an optional step. To disinfect your countertop, use a 50-50 solution of isopropyl alcohol and water. Use a spray bottle to mist the entire surface of your granite countertop. Leave for about 5 minutes and then towel wipe and dry.

Adding shine – A neat little trick to make your granite countertop really shine is to use any cooking oil to buff it. The key is to use very little. Apply a few drops on a fresh and dry soft microfiber towel and buff it into your granite, one small area at a time. Reapply oil as and when your towel runs dry. The very light oil coating will not only give your granite countertops a brilliant shine, but also further protect it against stains. Use very little oil. If your countertop is oily or slippery to the touch after this buffing, you have used too much oil.

Common Granite Countertop Cleaning and Maintenance Errors

Sometimes, it helps more to know what not to do than what to do. This especially applies to how you care for your granite countertops.

Granite countertop cleaning and maintenance DONT’S

- Do not use steel scrubbers or steel wool scrubbers. Resist the urge to scrub away stains with these scrubbers. They will leave scratches on your precious countertop!

- Do not use popular homemade cleaners like vinegar, lime etc. Homemade cleaning solutions are usually great as they are organic. But, when it comes to granite, vinegar, lime, lemon or citrus cleaning solutions are all a no-no. They all contain citric acids that can cause your granite to etch and look damaged. These acidic cleaning solutions also strip away the sealant on your granite countertop, making it susceptible to more staining

- Do not use ammonia based cleaners like Windex, Lysol and others – This is another common error. Besides potentially damaging your granite countertops by etching it, such cleaning solutions will also leave chemical residues that can mix with food you prepare and consume off your granite countertops

- Do not use bleach

- Do not use disinfecting wipes. It’s very convenient to use disinfecting wipes to quickly disinfect your granite countertop. But, most disinfectant wipes contain citric acid that will harm your granite, especially when you use them regularly!

- Do not use your granite countertop as a cutting board!

General Granite Countertop Maintenance Tips

- Clean up spills with a towel or sponge as and when they happen

- Blot up spills instead of wiping and spreading the stain on your granite countertop

- Use coasters

- Use trivets to avoid letting hot containers come in contact with your granite countertop

- Avoid storing containers like oil containers that are prone to leaks and drips onto your stone countertop

Sealing Your Granite Countertop

Depending on the type of granite you have chosen and how often you use your granite countertops, it might be required for you to seal your countertop every 6 months to two years. Sealing protects your granite against staining.

How do I know when my kitchen countertop requires sealing?

Take a little water and pour it onto your granite countertops. After 5 minutes, check to see if the water remains beaded or pooled on top of your granite countertops, like when you first poured it. If it stays beaded, your countertop is still sealed. If however the water has partially or fully sunk in, it is time for a sealing.

How to seal a granite countertop?

Buy any quality brand of granite sealer. Every manufacturer’s instructions will vary slightly. But, the steps below are usually what is recommended to properly seal a granite countertop.

- Clean and dry your granite countertop

- Spray the sealant and let it sit for 3-5 minutes

- Spray the sealant a second time and let it sit for another 30 minutes

- Use a fresh and soft microfiber towel to wipe off excess sealant that remains

- Your granite countertop sealing is done!

2022 has been a year where the use of white granites have been trending all over the world. One white granite in particular has seen significantly more demand than the others – We are of course talking about Viscount White Granite. Order Wholesale Viscount White Granite blocks and slabs.

Viscount White Granite – All You Need to Know about this Stunning White Granite

Where does Viscount White Granite come from?

Viscount White granite is exclusively found in India. Quarries in Southern India, particularly in the state of Andhra Pradesh, have rich reserves of high-quality Viscount White Granite. We at Katti-Ma granite have exclusive access to these quarries in the district of Madanapalle, Andhra Pradesh. We specialize in delivering both Viscount White granite rough blocks and slabs to customers all around the world.

This white granite with grey veins is simply stunning to look at. Customers around the world love to use this stone as countertops for the kitchen, bathrooms and even in general areas of the home. It is also becoming quite a popular choice as outdoor granite material as well. Used as wall cladding and in building facades, Viscount White granite can quickly add grandeur and sophistication to almost any architecture. Besides being beautiful and one-of-a-kind, Viscount White granite is also very durable, making it a practical choice as a kitchen countertop.

Viscount White granite goes by many names and spelling variations. Some of the most popular names for it include; Bianco Viscont White, Viscont White, Viskont, Wiscount White and sometimes even VW granite.

Viscount White Granite Colours and Aesthetics

As mentioned earlier, Viscount White is a white granite with swirly grey veins. However, these swirls can sometimes be white or even black in colour. What’s very unique about Viscount White is how the patterns change from slab to slab. The chaotic variations from slab to slab is what actually makes this a very desirable granite for use in interior spaces. It’s a granite with a lot of character.

The patterns on Viscount White Granite can sometimes even vary quite differently in the same slab. Patterns on slabs can also vary depending on how the Viscount White granite rough block is cut.

Another reason why Viscount White is very popular is because it is a much more cost-effective alternative to marble countertops. It is particularly sought after an alternative to the very expensive Calacatta marble.

- A Viscount White Gangsaw Slab

- Viscount White with beautiful dark veins running down the countertop

- A light veined Viscount White granite countertop

- Viscount White countertops in a modern kitchen

- Another beautiful use of Viscount White Granite in a kitchen

Viscount White Durability

Viscount White granite is very durable as it is a dense granite. The high-density often means that the stone has very little or even no fissure lines. The higher density also makes this granite less absorbent than most granites. Less absorbency of course means that it is more stain resistant than most light granites out there.

On a hardness scale, Viscount White granite comes in at 7 on the Mohs scale, making it a very hard and durable granite. Is Viscount White granite also heat resistant? The answer is yes, Viscount White is a heat resistant granite. One will have no problems using it to house stovetops where a lot of cooking is to be done.

Being a very hard granite, Viscount White is also quite scratch resistant. This again makes it a very practical choice as a kitchen countertop material.

Viscount White Granite Maintenance

Being a very dense granite, Viscount White will not need much of maintenance at all! But, sealing granite countertops made out of this material will help prolong and maintain the luster and beauty of this exotic white granite. Sealing is recommended once every year. Everyday maintenance simply requires a good wipe-down with a damp cloth dipped in water. One must avoid cleaning Viscount White granite with chemical cleaning solutions such as Windex. In fact, you must avoid chemical cleaning of any granite. If you must use cleaning solutions, look for granite-safe cleaning solutions and also test such solutions on a small area of your Viscount White granite countertop first.

Viscount White Finishes

Viscount White is available as either a polished surface or as a leathered surface. A polished finish is the most sought-after finish for this granite. But a leather finish has its uses and appeal as well, often used alongside polished Viscount White, to offer a bit of contrast.

There are other finish styles for Viscount White granite. They are; flamed, honed, brushed or bush hammered. But these finishes are not nearly as popular as the polished or leathered finish styles.

Is Viscount White Granite Better than Quartz Countertops?

This is a debatable matter. First of all, Viscount White granite is less expensive that comparable Quartz countertops. Viscount White granite is also an all-natural stone, while quartz is not entirely natural. Quartz countertops do however generally outperform granites when it comes to stain resistance. But with Viscount White being a very dense granite, the difference in this aspect is quite negligible. In other words, if you like the unique look of Viscount White granite, there’s no reason why you must pass on it for a Quartz countertop!

Viscount White Sizes

We at Katti-Ma Granite can provide you with wholesale Viscount White granite in any size you need. From shipping whole rough blocks to Gangsaw slabs (260×160 cm) to cutter slabs (180×60 cms), we can have your Viscount White granite delivered to you in 30 days or even less, in any port of your choice, almost anywhere in the world. Our Viscount White slabs are available in 2 and 3 cm variations. We also accept custom size orders.

Please see our Viscount White Granite product page for more details.

Why is Viscount White Granite so popular?

- Affordable – A great cost-effective alternative to marble, offering the same luxurious aesthetics. Also cheaper than aesthetically comparable quartz granites

- Heat-resistant – Making it an ideal countertop surface for a kitchen environment

- Stain-resistant – Viscount White is one of the most stain-resistant light granites out there

- Outdoor friendly – Can endure sunlight and UV exposure, without fading, for a long time

- Scratch-resistant – Can easily fend off nicks and cuts from knives, utensils and glass

Nền kinh tế xây dựng đang bùng nổ của Việt Nam đã cho thấy nhu cầu lớn về đá hoa cương. Trong đó, nhu cầu về đá hoa cương đỏ và đen của Ấn Độ là đặc biệt cao. Đá hoa cương Ấn Độ có đặc điểm là chắc chắn, độc đáo và quan trọng nhất là rất tiết kiệm chi phí. Nó cũng rất dễ bảo trì nên vô cùng phù hợp cho một thị trường mới nổi như Việt Nam.

Katti-Ma Granite là nhà xuất khẩu khối và phiến đá hoa cương bán buôn hàng đầu đến từ Ấn Độ, có trụ sở tại Chennai, Tamil Nadu, Ấn Độ. Chúng tôi sở hữu các mỏ đá và cũng có nhà máy chế biến phiến đá và tượng đài bằng đá hoa cương của riêng mình. Với hơn 40 năm kinh nghiệm phục vụ thị trường Mỹ, Canada, Úc, Trung Quốc, Đài Loan và nhiều thị trường quốc tế khác, chúng tôi hiện đã bắt đầu cung ứng sản phẩm cho thị trường Việt Nam.

Và, đây là các loại đá hoa cương Ấn Độ màu đỏ và đen vô cùng thu hút và độc quyền của chúng tôi.

Đá hoa cương Ấn Độ màu đỏ của chúng tôi

Đá hoa cương màu ngọc trai đỏ (Red Pearl)

Red Pearl là một trong những loại đá hoa cương đỏ giúp tiết kiệm chi phí của chúng tôi. Nó có thành phần màu sắc cân bằng độc đáo giữa màu đỏ sẫm với các vòng xoáy và hạt màu xám đậm. Loại đá hoa cương này là một sự lựa chọn rất phổ biến để sử dụng cho cầu thang, mặt tiền hoặc để ốp tường. Giống như Chilli Red, Đá hoa cương Red Pearl của chúng tôi cũng rất dễ bảo dưỡng.

Đá hoa cương Ấn Độ màu đen của chúng tôi

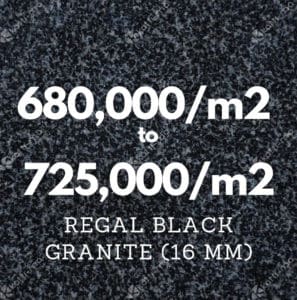

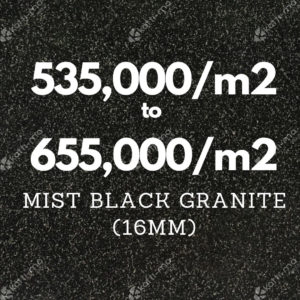

Ấn Độ có đá hoa cương đen tốt nhất trên thế giới. Và Katti-Ma Granite sở hữu bộ sưu tập chọn lọc kỹ lưỡng những loại đá hoa cương đen cao cấp nhất từ những mỏ đá hàng đầu ở Nam Ấn Độ. Một trong số những loại đá hoa cương đen nổi tiếng nhất của chúng tôi là đá Black Galaxy, India Black, India Mist, Black Forest, G20 và Regal Black.

Vui lòng xem bảng giá đá hoa cương đen Ấn Độ của chúng tôi trong hình bên dưới.

Đặt hàng từ Katti-Ma Granite

Vui lòng liên hệ với chúng tôi thông qua Zalo bằng cách bấm vào nút chat bên dưới. Katti-Ma Granite có thể cung cấp đá hoa cương đỏ hoặc đen cho quý khách trong vòng 15 ngày kể từ ngày đặt hàng. Cần hàng mẫu? Vui lòng yêu cầu hàng mẫu qua Zalo và chúng tôi sẽ gửi mẫu cho bạn chỉ sau khoảng 5 ngày.

Chúng tôi có nguồn cung cấp đá hoa cương đỏ và đen chất lượng gần như không giới hạn và hoàn toàn đủ năng lực để trở thành nhà cung cấp bán buôn đá hoa cương đỏ và đen trường kỳ cho doanh nghiệp hoặc mối làm ăn của bạn. Chúng tôi có thể gửi hàng đến Hải Phòng, Đà Nẵng, Qui Nhơn, Thành phố Hồ Chí Minh và các cảng khác. Để đặt hàng, vui lòng liên hệ qua Zalo.

Black Galaxy granite is the quintessential choice of granite stone for both residential as well as commercial building projects. The iconic gold specks hurtling through a black background mimic an expansive galaxy, giving this famous granite its signature name and worldwide appeal. Robust in build and very easy to maintain, it also has the ability to seamlessly blend into almost any exterior and interior design theme.

Saudi Arabian customers looking for wholesale Black Galaxy Granite now have access to this high quality and versatile granite from Katti-Ma Granite (India), a 40-year-old leader in the field of wholesale granite exports to all parts of the world.

Learn more about how and why you must source Black Galaxy from Katti-Ma Granite.

Why Choose Katti-Ma Granite for your Black Galaxy Granite Needs in Saudi Arabia?

Katti-Ma Granite Owns and Operates Its Own Granite Factory, Capable of Delivering Rough Blocks and Slabs

Katti-Ma Granite offers a distinctive cost and logistics advantage because we own our own granite factory, in the port city of Chennai, Tamil Nadu, India. Besides being equipped with state-of-the-art equipment for granite rough block processing, we also have a granite monument wing capable of cutting rough blocks into granite slabs.

So, whether you need Black Galaxy Rough Blocks or Slabs, we at Katti-Ma have the ability to deliver exactly that, at very competitive prices and in expedited time frames, as explained further below.

Competitive Black Galaxy Granite Pricing

Our long-term and exclusive sourcing arrangements with one of the biggest and best Black Galaxy granite quarries in India, streamlined transport and delivery logistic systems and the use of our own port-based factory in Chennai gives us the edge when it comes to pricing. Below is an indication of current Black Galaxy granite prices customers in Saudi Arabia can expect to pay when ordering from us.

Black Galaxy Granite Prices in Saudi Arabia

| FOB Prices (Chennai / Vizag Port) | |

| Cutter Size (16 mm) | Gangsaw Size (20 mm) |

| Price per sq.mt | |

| $27 to $35 | $41 to $68 |

Need Black Galaxy Granite in Saudi Arabia?

Send us a message with your Black Galaxy Granite requirements and we will get back to you in 1 business day or less!

Single Quarry Source – Consistent and Ongoing Availability of Quality Black Galaxy Granite

Katti-Ma has exclusive access to the best and biggest quarry for Black Galaxy granite in India, situated in the state of Andhra Pradesh. Whether you need just one or two containers of Black Galaxy Granite in Saudi Arabia or are in need of a much larger consignment that needs to be delivered on regular or scheduled basis, we can deliver, month after month, year after year.

A single quarry source allows us to deliver consistent quality, pricing and availability.

15 to 30 Day Black Galaxy Granite Delivery to Saudi Arabia

With 40 years of experience, we at Katti-Ma Granite have the ability to deliver your consignment of Black Galaxy Granite to Saudi Arabia in as little as 15 days from the date of order. Delivery timelines can however vary between 15 to 30 days, depending on a few factors such as time taken for government clearance and also based on usual vagaries in sailing and port transit times.

No-Risk Letter of Credit Payment Process

Buy with confidence using a Letter of Credit from your bank. Your funds deposited in your own bank are cleared and transferred to us ONLY after your consignment of Black Galaxy Granite has satisfactorily reached your port of choice in Saudi Arabia.

We Ship to Multiple Ports in Saudi Arabia

We are currently able to immediately ship to Dammam, Jizan or the Dhuba port in Saudi Arabia. Other ports can be serviced as well. Please contact us for more details.

We Have Other Blacks and Other Exclusive Colours

Need more than just Black Galaxy Granite? Katti-Ma can be your one-stop-shop for granites in many more shades of black and other colours. Below is a sampling of other granite colours available at Katti-Ma. To see our full range, please see our entire range of granite rough blocks and granite slabs.

Our Other Black Granite

- Regal Black

- Black Forest

- India Black

- India Mist

- Black Pearl

Our Exclusive Colour Granite

- Chilly Red

- Cladon Blue

- Elephant Grey

- Steel Blue

- Red Pearl

About Katti-Ma Granite

Katti-Ma Granite is a multiple-time award winning exporter of whole granite blocks, slabs, monuments and granite art. Over 40 years, we have developed long-lasting relationships with customers all around the world, including customers in USA, Australia, Canada, Taiwan, China & more. You can learn more about us here.